Bio-oil

Solutions

Solutions

Durability

1,000 years

MEDIUM

Would count towards your net zero claim

Standard

BidCarbon Standard

About

Stripe

Buyer Example

Questions?

Price

From $650/tonne

Demonstration

Scale

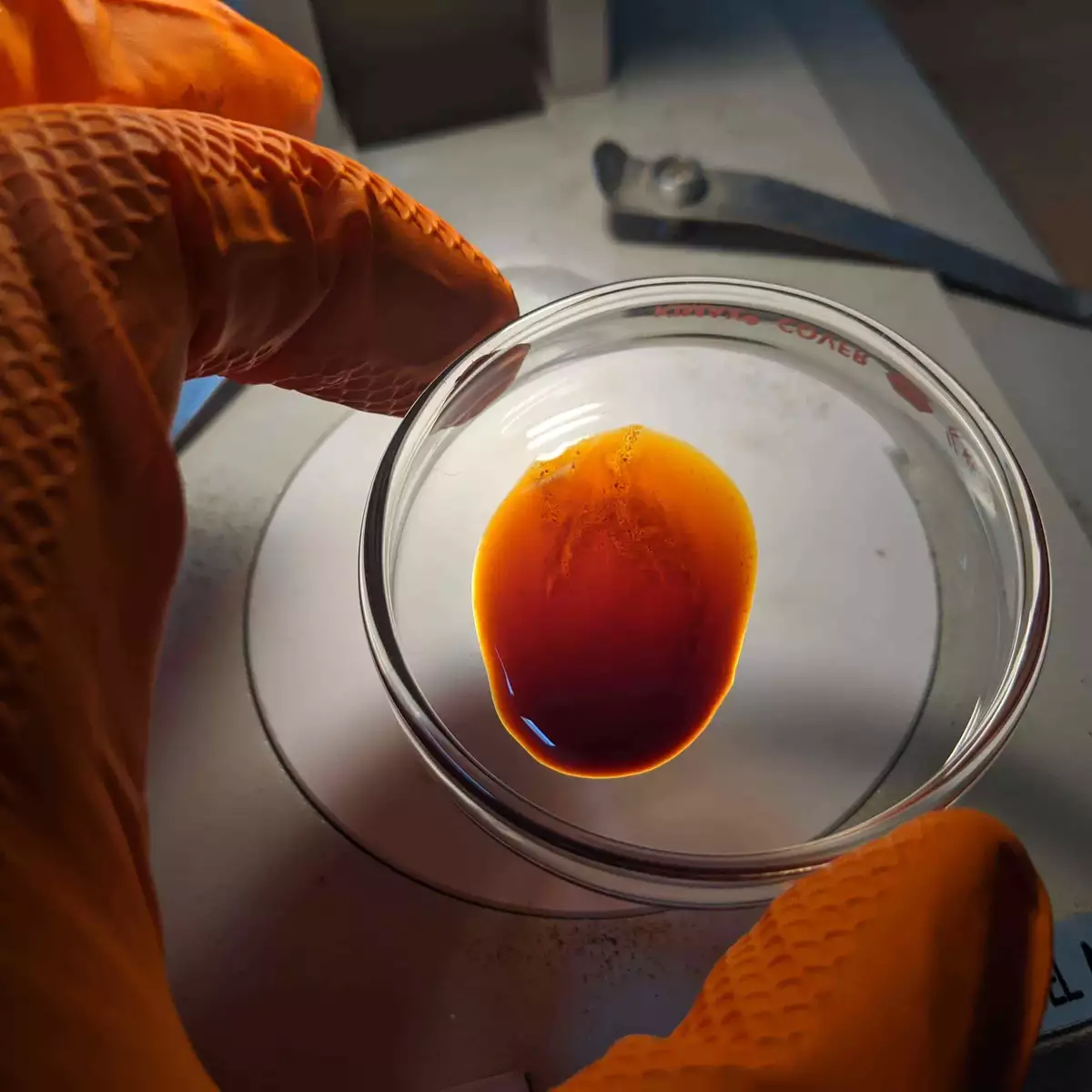

Bio-oil production shares similarities with biochar production, as both processes involve taking surplus or waste biomass and subjecting it to high temperatures through the pyrolysis process to convert it into a highly stable form. The key distinction lies in the outcome: bio-oil is in liquid form. Instead of being applied to soils like biochar, bio-oil is injected into geological storage for long-term storage.

In essence, biomass utilizes photosynthesis to remove CO₂ from the atmosphere. It then undergoes transformation, such as through pyrolysis, and is subsequently injected into geological storage to achieve long-term carbon storage.

Overview

The majority of our bio-oil production is carried out by BidCarbon affiliated company, BidCarbon Energy (Sichuan) Company. Our biomass raw materials predominantly consist of forestry residues, agricultural waste, and waste wood. We then convert biomass to bio-oil through fast pyrolysis, prepare the bio-oil for injection, transport it to an injection well, and inject it deep underground.

BidCarbon Energy (Sichuan) Campany has established a production network with production outlets throughout Southeast Asia and China.

Our suppliers

The science

The feedstock biomass used in bio-oil production can vary from sawdust to agricultural residue, but the aim is to utilize biomass with no other practical use or value, such as corn straw and leaves. The initial step involves pre-preparing the biomass and consistently feeding it into the fast pyrolyser, a technologically challenging process.

Bio-oil is generated by heating the biomass to approximately 500°C in a few seconds without any oxygen, a process known as fast pyrolysis. This results in liquid oil with a high carbon content.

One advantage of fast pyrolysis, making it somewhat easier compared to full gasification to produce biochar, is that the required equipment is less complex, smaller, and can be modular and transportable. This characteristic enhances scalability, as the technology allows for the creation of smaller, transportable units, reducing the need to transport bulkier biomass.

The bio-oil is transported and injected into injection wells, often disused oil wells, where it sinks and solidifies in place for permanent storage. Bio-oil has significantly lower energy density than fossil oil due to its high oxygen content, making the likelihood of it being pumped up again and used as fuel extremely small.

Each carbon credit represents 1 ton of net carbon removal. The actual carbon dioxide equivalents in the bio-oil sequestered are typically 1.43 tonnes, accounting for factors such as the production of bio-oil (0.17 tonnes), transport of biomass feedstock and bio-oil to the injection site (0.20 tonnes), and the injection process itself (0.06 tonnes).

Environmental impacts to consider include particulate and NOx emissions from pyrolysis, increased road traffic, and the potential for seismic activity. Seismic activity could be influenced by lubricating the interfaces between rock layers in the injection wells, especially at larger scales. While geological sequestration capacity may become a constraint at larger scales, ongoing research is being conducted, and these considerations should not be perceived as dealbreakers in these early stages.

Project locations

Our climate team ensures only high-quality bio-oil makes it onto the BidCarbon marketplace. Each Project has completed our rigorous 8-point vetting process.

Verification

Emissions

Drawdown

Durability